Enginursday: Supplies!

A look inside some common power supplies.

Introduction

Power supplies are everywhere these days. With the advent of switching power supplies, the cost of high-current supplies has radically dropped. Maybe you've noticed how the large, heavy, wall-wart style adapters are no longer lurking around your baseboards, falling out of their sockets? Or occupying several of your valuable power-strip positions? But not all power supplies are created equal.

Whenever I get disgusted by a power supply, I inevitably tear it apart, judge it, and throw it at my power supply box of shame. There are so many of these light-weight supplies out there today that my collection is constantly growing and evolving based on what I deem to be a good supply.

This article takes a cursory look at what's typically inside, and what quantities are measured during validation of a supply.

Engineering Triangle

Before I get into the meat of it, consider this diagram commonly presented as engineering curriculum.

This diagram is used when looking at products from a very high level. A customer may ask for a product that has tons of features, is super cheap, and was available yesterday. At this, the engineer scoffs and says "pick two." It can be made quickly and with high quality, but it will cost a lot. Or, if you find it fast and cheap, perhaps the quality is suffering.

The triangle is applicable to power supplies because they take a great deal of work to make well, yet customers are crying for cheap supplies. As a supplier of electronics, it's a constant struggle and compromise.

Certification Marks

Take a look at the nearest power supply labeling. It will hopefully have a slew of marks on it that indicate what standards it abides to. Politically, each country is a little different and thus has different ideas of which standards are relevant, so naturally a product with a worldwide customer base is going to have many of these marks (check out your laptop's power brick).

Or, if the product is destined for America, it might only have a UL mark.

I found a website that lists various marks with picures. I have to ask myself, "What's to stop people from just printing the logo on the label?" There's a huge fine involved if the agency catches you, but if the product is coming from some unknown supplier it can be dicey. One common thing to do is to print the "CE" logo with the 'C' and 'E' spaced closer together, which is known as a China Export and doesn't have anything to do with what we call CE.

What's in a Supply?

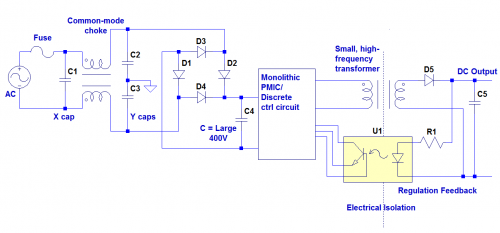

Without describing the math behind how to select component values, here's a basic example circuit of what's inside an AC-DC switching supply.

Parts of the circuit:

- Fuse -- Prevents fires

- X and Y caps -- Named by their shape in the circuit, these provide high frequency shunting to chassis for noise control.

- Common mode choke -- Cancels common-mode noise on the input wires

- Diode bridge -- Steers the AC into DC

- Primary-side cap -- Smooths rectified AC into useable DC at a high voltage

- PMIC -- Power management integrated circuit, or collection of discrete components that act to switch the transformer's primary side

- Transformer -- Provides isolation and ratiometric scaling of power down to the desired voltage

- Secondary side Diode -- Rectifies back to DC

- Feedback coupling -- Provides information about output voltage for the PMIC's decision making process

Also, sometimes I refer to the primary side components as the "high side" and secondary as "low side."

Tear-downs

Molex-pinned Supply

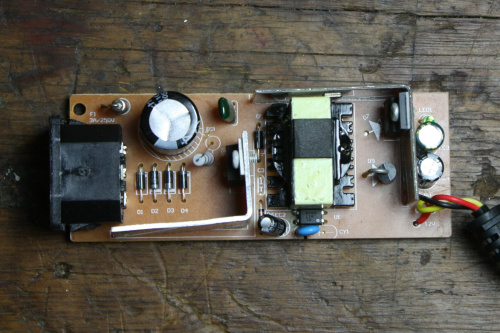

This is our 12V/5V Power Supply. Judging from the comments, customers absolutely love this supply. Oh wait, I think I read that wrong. This supply is just $9.95. Looking at the engineering triangle, something else has to give.

Let's have a look!

This first picture shows the label. The nested squares indicate double insulation and thus no chassis ground required. The enclosure is all plastic. Oh no, that 'C' and 'E' are too close together!

There's really not much in this power supply. No line filtering is present but we do have a fuse. The large cap to the left is rated 400V so this supply should be good world-wide, as indicated by 100-250VAC input rating on the label. On the right you can see a couple diodes (one is TO-220 packed), with two output caps, one for each voltage. These output caps are only rated 10 and 16 V, which is in the spec but isn't the best. I've seen broken supplies with wild outputs and blown caps, so I'm not surprised. Specifying high quality caps with solid margin contributes directly to price.

Here we can see how the output of the transformer is wired. It has three secondary terminals, one of which is connected to something like a ground plane, common to all electrolytic caps and the output. Assuming this is a tap point of the windings, the other two terminals are coils to the 12V and 5V rails. Each has a single diode so that during the positive and negative phases, the transmitted flux works on alternate output rails to balance the load.

Notice the slot underneath the optocoupler. This will come up again later. It's to prevent creepage of electrons along the surface of the soldermask from reducing the high-voltage standoff of the isolation region, which can be seen as the area under the transformer that is free of copper. Also straddling this slot is a cap designed to provide a path for high-frequency noise back to the neutral wire of the supply.

I noticed that the primary side of the transformer actually has two windings, then noticed that there are some diodes and a couple transistors associated with the extra winding. These form an oscillator that drives the 4N60 power NMOS, which is hanging out by the primary-side bulk cap.

All in all, this supply is fairly clean but doesn't have any features. We'll put it in the "Fast and Cheap" side of the engineering triangle. It doesn't have regulators on the secondary side, so loading down one of the output rails probably causes the other one to do some funny things. I wouldn't use this on a valuable hard drive but could re-regulate the output, or supply tolerant loads with it.

Google USB Adapter

I saw this cute little Google branded USB output adapter at the thrift store and couldn't resist buying it to take apart. I'll probably tape it back together and get some use out of it afterward.

From the top side we can only see a few things:

On the high side, there are two caps (400V rated), a 3N4 marked TO-92 (probably a high-voltage mosfet) and a couple resistors. No fuse, so hopefully the 10ohm marked resistor in-line with the line terminal acts as a PTC (positive temperature coefficient) device to protect us from fires.

On the low side, there's nothing but a couple of caps and a USB port visible. No feedback network.

Following the flow of power, the line first encounters a bridge rectifier and then fills the two storage caps. This view reveals a similar circuit to the molex output supply, in that it has extra windings and a diode for some high-side biasing circuitry/measurement coil. Rather than two discrete transistors for an oscillator, this carries a SOT23-5 IC, which is probably a PMIC of some kind. Notice that on the low side, there's an additional diode and two resistors – that's it. There's no feedback path so regulation must occur in another way: primary side regulation.

Primary side regulation is the act of regulating the output of the secondary winding by only measuring and manipulating the high voltage side of the transformer.

I actually wanted to see what the output looked like but the supply did not come on! OK Google...

Li Shin International Laptop-Type Supply

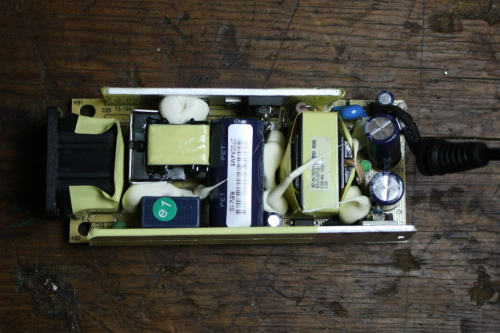

I grabbed this one from the thrift shop because it boasts 3.3 A at 12 V and I thought it would be useful. But then I took it apart because that's what I do with all my favorite toys.

I've had a few of these Li Shin International supplies in my life and I've never had a problem with them. Typically, they're used for laptop supplies but work great for anything at the right voltage. It used screws for the case, and I even noticed that the case is shot with UL listed plastic, which is a good sign.

The first thing that struck me was the size of that high-side cap in this supply. It's so big they used it as a place to put their manufacturing-process label, a common problem when board space is at a premium. The next thing I noticed is the big blue box with the e1 sticker. This is the X cap. Down at the surface level you can see a green, pea shaped cap (later I determined this to be a fuse-like protection device), which is a Y cap, plus some empty sections where other caps could be placed -- provisional Y caps. This tells me the corporation at least has people working who have done line noise tests before and gave it a shot. As a best case, they performed and passed their emission testing without needing to populate the additional components.

Speaking to quality, this has two 16V 1000 uF caps on the low voltage side, and is a 3.3A 12V supply. Our Molex output supply had a single 16V 1000 uF cap for a 2A 12V supply, yet the cap volume was about half. By volume, this supply has four times the cap for less than two times the current. I suspect these caps have more insulation and electrolyte, and will last much longer.

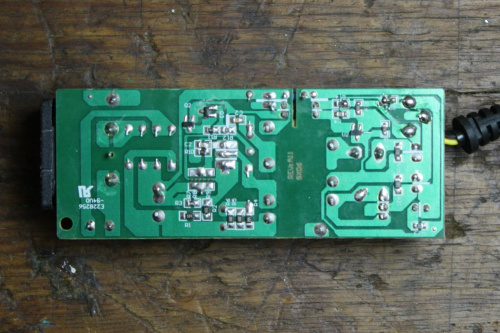

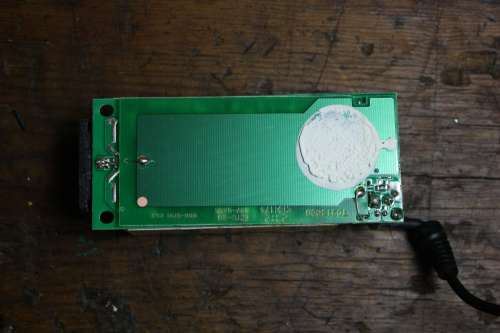

Under the PCB the design becomes more clear.

The left third:

- The two outer pins of the IEC plug route to the various Y cap positions, which couple back to chassis ground.

- The green pea is the upper leftmost component, and can be seen to interrupt the circuit in series so it must not be a Y cap, but actually a fuse-like protection device of some kind.

- The four pins in a square are the common-mode choke.

- You can find the X cap across two of the terminals of the common-mode.

- After the common-mode choke, the four inline pins are the bridge rectifier.

- Next comes the high-voltage cap.

The middle:

- Right off the high-voltage cap there's a mosfet along the lower edge.

- There's a high impedance tap for the SOIC-8 IC, the PMIC for the supply -- to get it charged and switching before the self-supply is operational.

- Near the top, the wide spaced four pins of an opto-isolator can be seen, spanning the isolation region.

- The transformer has four high-side terminals. Two of the terminals are associated with the switching mosfet, while the other two have a cap and single diode -- a supply for the PMIC once it's started.

The right third:

- The output two pins of the transformer are near the middle of the mess.

- An unpopulated SOIC-8 footprint exists, probably for a second output voltage option.

- A TO-220 near the top edge rectifies the output AC to DC.

- Output caps are along the right edge.

- The drive side of the opto can be seen at the top, with some biasing resistors.

- The shield PCB is connected at the DC ground connection.

The shield PCB connects the output DC ground all the way back to chassis ground. For this supply, probably intended for a laptop, this means that static charge - and other faults to the laptop case - should safely be routed back to the grounding system of the building it's being used in. As the output side of the transformer is isolated from the input side, the chassis is still isolated from the mains.

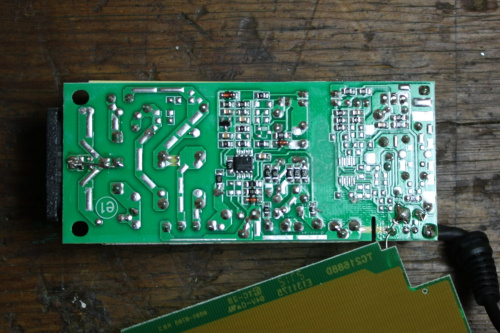

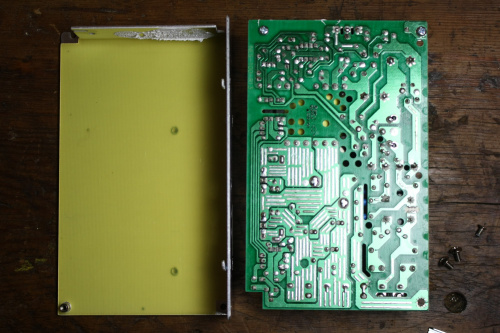

MeanWell

Here's a supply we're currently vetting. The sticker (pictured above) claims it can deliver 20 A of current at 5 V. Excellent!

A view from above -- the design is neat and tidy. Generally, power flows from the lower left, up and around in a U shape, then out the lower right.

The circuit starts with a fuse, X cap, common-choke, another X cap, diode bridge, and high-side capacitors. This supply uses two 200V caps in series, but I don't understand how it works yet. There is a 115-230V selector switch for line voltage that plays with the bridge. Along the edge of this high voltage section, Y caps couple to chassis across a routed-out barrier, like in some of the other supplies.

The PMIC is the 8-pin DIP in the upper right, a TI 3845. It controls the switch (on the top heatsink) and gets regulation information back. Like some of the others, there's a spare winding on the transformer to power the PMIC.

After the transformer it's all rectification, storage, and feedback.

The bottom side reveals the chassis ground stub (third screw terminal from the right) that all the Y caps come to, and the slotted/drilled isolation barrier, though those holes might be for some notion of air cooling. On the low side, current is increased so many of traces have the solder mask opened for additional solder. This can decrease resistance of these traces, as explained and tested by Dave of EEVblog in Episode 317 - PCB Tinning Myth Busting.

I also found it interesting that they put silkscreen on the non-component side, but not for aesthetic reasons! If you look closely there are black lines drawn between some of the pins. I suspect this is to aid in the wave soldering process to prevent bridges.

Electrical tests

A lot can be determined from looking at layout and identifying name-brand components, but it doesn't tell much about how good the supply is at generating DC. It's not really in the scope of this article, but I wanted to touch on a few key qualifications of a power supply. The manufacturer tested them at the factory, but how rigorous were they?

Load Regulation

How good is the supply at controlling its output voltage for various loads and input conditions? Does the voltage output of the supply change with different loads?

This can be measured by using Ohm's law to determine resistances that can test any gradient of loads within the supply's range.

Output Ripple

The supply switches at a high frequency so the output must have some ripple. How much is it? Are the downstream components capable of dealing with that ripple?

This can be measured with an oscilloscope and presented in units of voltage or as a percentage. Set the scope to AC coupling with trigger at zero, and use the cursors to get a peak-to-peak value.

Transient Response

If the load suddenly changes, what happens to the regulation? How long does the supply take to regain control of the output?

Use a low-bounce switch to switch in a near-rated load. The voltage will sag, prompting the PMIC to increase duty cycle/frequency. The output can overshoot the target voltage, causing a potentially harmful spike on the line. This can be captured with an oscilloscope.

Efficiency

The goal is to make the supply 100% efficient, but that's not realistic. In fact, efficiency may only be rated at a peak, and at other operation points it could be substantially lower. This is important because extra power lost in the supply costs money, and more importantly, creates heat.

A power supply's efficiency is measured by dividing the output power by the input power, over the operating load range of the supply.

Switching Frequency

What frequency does the supply use to generate the output? Is it fixed in a range, or wild depending on load?

Set up an experiment to measure output ripple, and make a chart of frequency vs. load, or vs. input voltage, or whatever conditions the supply is expected to operate within.

Environmental Screening

Does the power supply work at all temperatures it's rated for? A common thing to happen at extreme temperatures is that a power supply will fail to come up. It might work once going, but will never start. Have you ever had a device that works fine indoors but won't turn on while cold? Even though it works at room temperature, some component has probably failed.

This may be out of the realm of hobby for most, but the test is valid. It's performed by running all the other tests inside an environmental chamber at various temperatures.

You may start to see that number of tests required to qualify a thing gets exponentially bigger when adding parameters to modify. High-quality power supplies may have gone through months of tests before they were qualified.

Conclusion

I've really only touched on the basics. I wanted to go through the process of testing these supplies, but it wasn't in the scope. Perhaps another Enginursday will feature some of the data.

I hope you've found this informational and are now able to identify some of the components you may find in supplies, and have a better understanding of what they're for. I learned a bit myself by opening some up, and hope to help bring high-quality, medium-priced supplies to the storefront in the future. Let me know what you think!