Headers or No Headers?

Some surprising findings about a recent product release

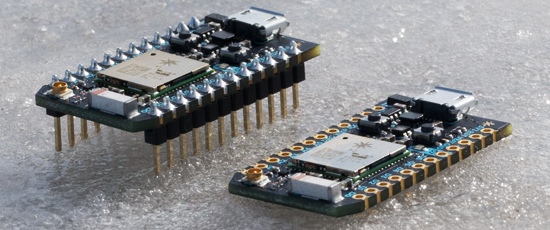

We were surprised recently when we launched two versions of a popular board - one with headers and one without - and the one with headers outsold the other 3 to 1.

The boards sell for the same price, but our own engineers design PCBs and most often prefer boards without connectors populated, as they need to solder in connectors or wires in any orientation they need. A number of SparkFun production techs are expert solderers and can solder as well as most of us walk and never have to endure the pain of having to remove pins and solder from a board.

There are also a multitude of 0.1” spaced headers out there, and that often factors into our decision not to include headers. By leaving the vias open, we give the customer the freedom to use the headers they feel will best work for them.

A board without headers is also ultra-thin and lightweight, and can more seamlessly fit into a completed project. One of our all-time top selling boards is small and has a flexible form factor – the Arduino Pro Mini. A customer commented, “No headers makes it easier to put an Arduino in a permanent project.” Soldering is often thought of as “a skill that everyone should have.” Here is some good information on how to solder pin headers to an Arduino Pro Mini.

For these reasons, we have come to believe that a majority of our maker audience prefers to hand solder pins according to their own specifications.

However, we do understand that beginners can get into a mess as they learn how to solder, and can even fry a few boards along the way. We occasionally also hear feedback such as this product comment, “I didn’t realize I had to solder the pins on myself,” and this one from a reddit thread, “Soldering those header pins is kind of a &^%$#*#%&.” Because of this, SparkFun does make some boards with headers already soldered on. After all, they have to be soldered in straight or they won’t line up properly with the headers on the breadboard and connections will be lost. Buying a board with headers can help make your system less flaky.

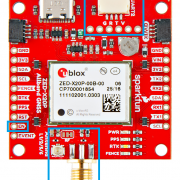

Another reason we make some boards with headers is to make prototyping (and breadboarding) easier. Boards with headers are good for those who want to plug in shields without any soldering. The headers often plug directly into standard breadboards and perfboards, and can also be mounted on a PCB.

How about you? Would you pay a little more for a board with the headers already soldered into place, or do you prefer boards to be stripped down to the essentials for embedded devices? Have your preferences changed as applications shift from projects to prototyping?